Waterborne Polyurethane Resin in Garment Silk Screen Printing ink

Jul 05, 2024

Introduction

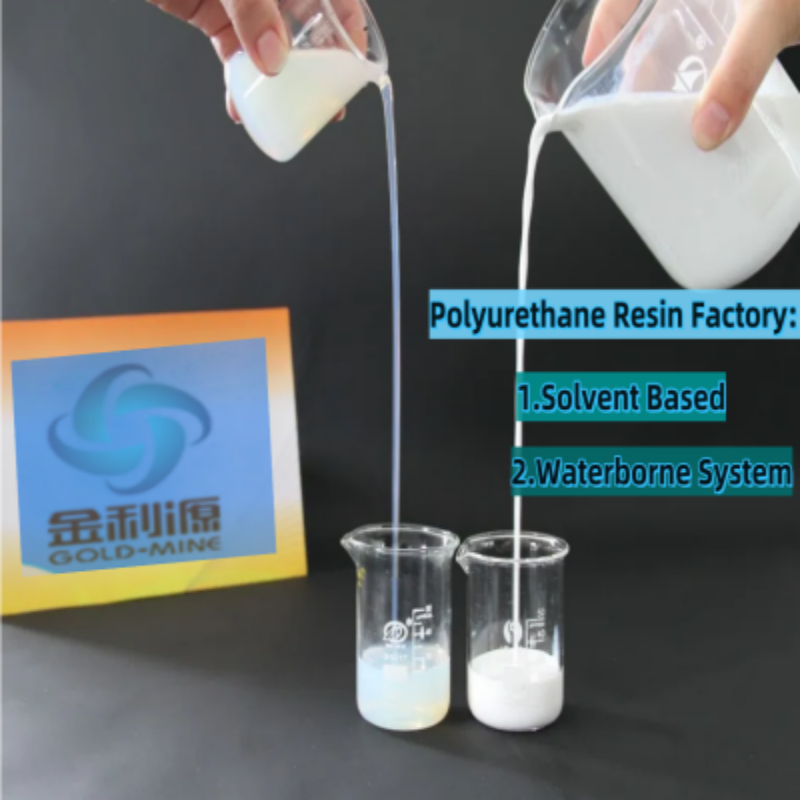

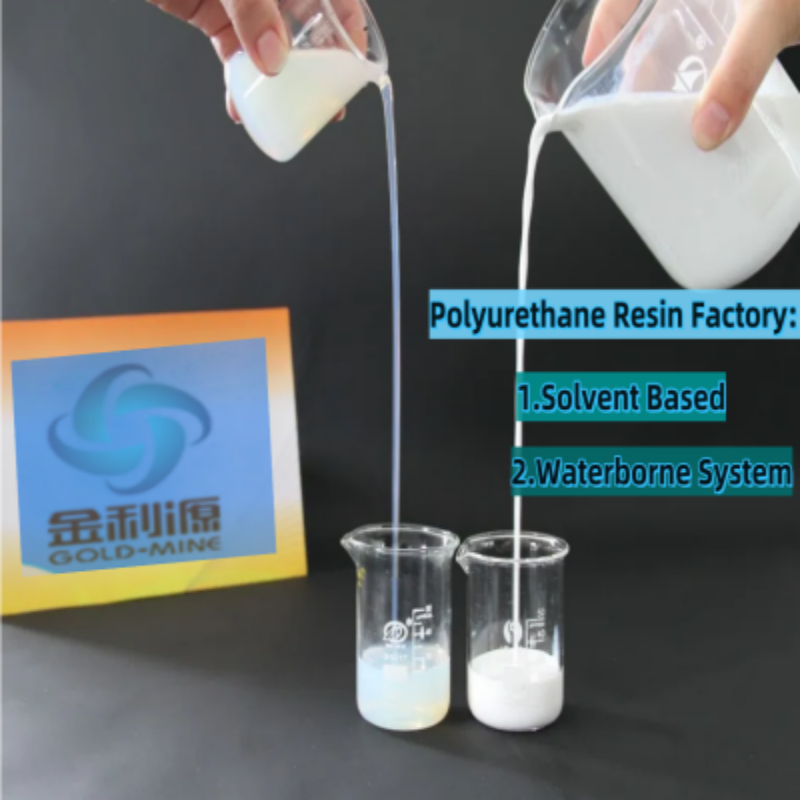

Silk screen printing technology is widely used in the textile printing industry due to its wide applicability and cost-effectiveness. In recent years, the market demand for environmentally friendly and high-performance printing materials has continued to grow, prompting researchers and developers to look for new printing materials. Waterborne polyurethane resin, with its unique physical and chemical properties and environmental characteristics, has become the preferred material for printing paste formulations.

-

Molecular Structure and Dispersibility

-

The molecular chains of waterborne polyurethane resin contain urethane bonds and ionic groups, which can form stable aqueous dispersions that are easy to apply evenly on fabrics through silk screen printing methods.

-

The dispersion of the resin in water reduces the use of organic solvents, thereby decreasing volatile organic compound emissions.

-

Viscoelastic Properties

-

Waterborne polyurethane exhibits good viscoelasticity, which means that the printed layer, after curing, has sufficient softness to adapt to the stretching of the fabric, while also being hard enough to ensure the clarity and abrasion resistance of the printed pattern.

-

By adjusting the molecular weight and crosslink density of the resin, its viscoelastic properties can be optimized to meet the needs of different fabrics and applications.

-

Adhesion

-

The polar groups in waterborne polyurethane resin, such as urethane and urea bonds, can form strong interactions with cellulose and synthetic fibers, thereby improving the adhesion of the print.

-

By modifying or adding appropriate crosslinking agents, its adhesion performance on non-polar fabrics can be further improved.

-

Chemical Resistance

-

Due to the presence of urethane bonds, waterborne polyurethane has excellent hydrolysis and chemical resistance, allowing printed products to maintain stable performance in a variety of environments.

Technical Analysis and Application

-

Optimization of the Printing Process

-

By adjusting the rheological properties of waterborne polyurethane, better printing effects can be achieved. For example, high viscosity at low shear rates is conducive to the stability of the printing paste on the screen, while low viscosity at high shear rates facilitates the passage of the paste through the mesh.

-

During the drying process, the moisture evaporation rate of waterborne polyurethane resin is controllable, helping to achieve rapid and uniform drying, avoiding problems such as screen blocking and uneven printing.

-

Improvement of Print Quality

-

Leveraging the excellent flexibility and stretchability of waterborne polyurethane resin allows for more vivid and durable printed patterns that are not prone to cracking and peeling.

-

Through formula optimization, the gloss and color vividness of the printed layer can be improved to meet the aesthetic requirements of high-end textiles.

-

Environmental Protection and Safety

-

The use of waterborne polyurethane binder significantly reduces the use of harmful solvents, improving the safety of the working environment and reducing environmental pollution.

-

Compliant with strict international environmental standards, such as the EU's REACH regulations and the EPA standards in the United States, helps to open up broader markets.

-

Practical Application Case

A leading textile printing company has achieved durable and excellent handfeel printing effects on a variety of fabrics using waterborne polyurethane-based printing paste. The successful application of this product not only enhanced the market competitiveness of the product but also met the most stringent environmental standards, showcasing the tremendous potential of waterborne polyurethane in the field of silk screen printing.

Conclusion

The application of waterborne polyurethane resin in the field of silk screen printing demonstrates its excellent physical and chemical properties and environmental advantages. Through a deep understanding of these properties and continuous technological innovation, waterborne polyurethane can not only achieve high-quality printing effects but also promote the textile printing industry towards a more environmentally friendly and sustainable direction. With the continuous emergence of new technologies, it is expected that waterborne polyurethane will play an increasingly important role in the future silk screen printing market.