Item NO.:

JLY-ZM50Application:

As rheological agent for ink,patint&coatingSolid Content:

50%Clour:

Transparent with light yellow liquidSolvent:

Water or environmental hydrophilic solventDescription:

JLY-ZM50 is a polyether type polyurethane associative thickener(rheological agent) with medium shear viscosity. It exhibits high viscosity at low shearing rates and good pseudoplasticity, as well as excellent flowability. It is used in coloring systems, and its excellent dispersive properties help to wet and disperse pigments in the formulation, resulting in a uniformly rich and full-bodied coating without affecting gloss condition

Application

Such as water-based synthetic leather, water-based coatings, water-based adhesives, etc. CombiningJLY-ZM50 with cellulose ether types or polyacrylic acid types of thickeners can provide the coating with better flowability and anti-splash properties. It can resist microbial degradation and its thickening capacity depends on the structure, particle size, and emulsifier of the latex as well as the film-forming agents and surfactants in the coating.

Technical Data

|

Item |

JLY-ZM50 |

|

Appearance |

Transparent with light yellow liquid |

|

Solid Content (%) |

50±1(150℃,45min) |

|

Viscosity(mPa·S(25℃)) |

5000-8000 |

|

Lonicity |

Non-ionic |

|

Solvent |

Water or environmental hydrophilic solvent |

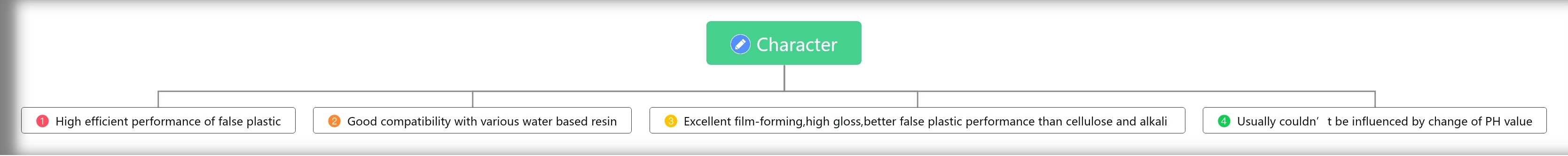

Character

1.Free of toluene, organotin, APEO, and other toxic substances;

2.Nonionic, performance is not affected by the pH of the system;

3.No adverse effects on the gloss of formulated products

Usage and dosage

Can be added at the grinding or paint mixing stage or after adding the emulsion. It is recommended to add 0.5-3% (of the total formula). The exact amount added should be determined based on different formulas and required viscosity. For better dispersion and to avoid lumping, it should be diluted with water or solvent before adding in a ratio of 1:1.

Notes

Associative thickening is affected by temperature. At low temperatures, the viscosity is higher, while at high temperatures, it is lower. The temperature conditions should be considered when designing the formula;

When the batch of thickened raw materials changes, the experiment should be repeated to determine the amount of thickener;

Its own viscosity has temperature effects, so it is easy to pump above 20℃.

Storage and expiration

It can be stored in its original closed packaging within the temperature range of 5℃~35℃for one year.

Package

125Kg、50KG/Drum